We got the rudder out for overhaul.

The rudder shaft was a bit of a mess, which would explain why the rudder was so stiff – it was virtually impossible to turn by hand.

There are 3 bearings on it. The bottom one was OK, the middle one was seized onto the rudder shaft so it must have been turning inside its sleeve instead of the rudder turning inside it.

There is bad corrosion under where the top bearing is located.

At this stage we have no idea how to fix the corroded part. Maybe a stainless steel sleeve, but that would mean reaming out the bearing cup … something that should have been simple is becoming a big task.

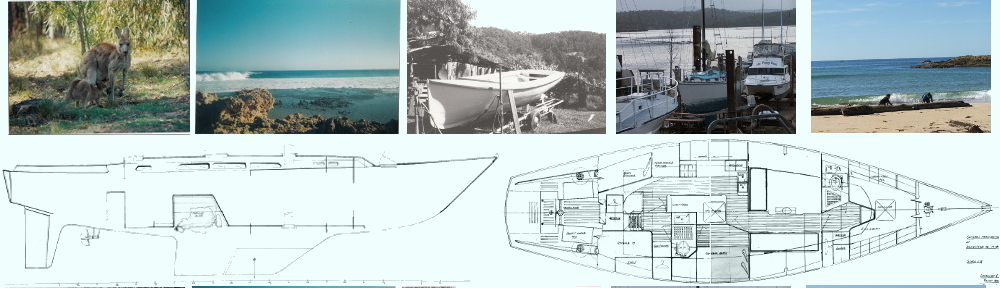

A big hole to fill

The next task is to reconstruct the stern of the boat. Originally the boat had a large open cockpit in the stern. We have decided to make it into a center cockpit with a small cabin in the very aft.

So, we cut out the old cockpit leaving a very large hole to fill

If you didn’t care

What happened to me

And I didn’t care

For you

The new aft cabin and cockpit will be constructed out of plywood and spotted gum framing. The first step is to construct something to around the existing cockpit to fix the new plywood to.

The first bit of the framing timber is in place, epoxied and fastened with stainless steel screws.

We would zig zag away

Through the boredom and pain

Occasionally glancing up through the rain

Window infills

There is still a bit of tidy up on the windows in-fills to do. They have been faired on both sides and sealed with everdure epoxy.

The final step is to cover the entire sides with 225 glass matting soaked in epoxy resin. That should make a nice strong watertight job of it.

Wondering which of the brothers to blame

And watching

For pigs on the wing