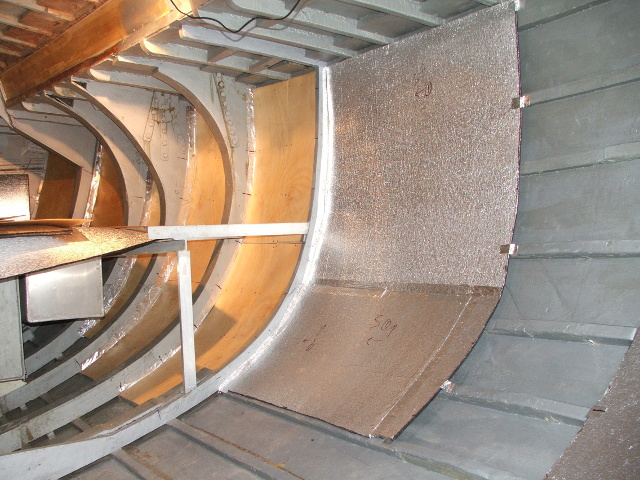

Its been a while but the insulation in the main cabin area is moving along.

The strategy is to sandwich the insulation between the top of the stringers and some very thin (3-4mm) plywood. All the ply has been sealed with epidure epoxy on both sides to minimise chances of rot.

This gives a 30mm air gap (the height of the stringers) between the insulation and the inside of the hull. According to the documentation, this is just about perfect to get maximum radiation reflection.

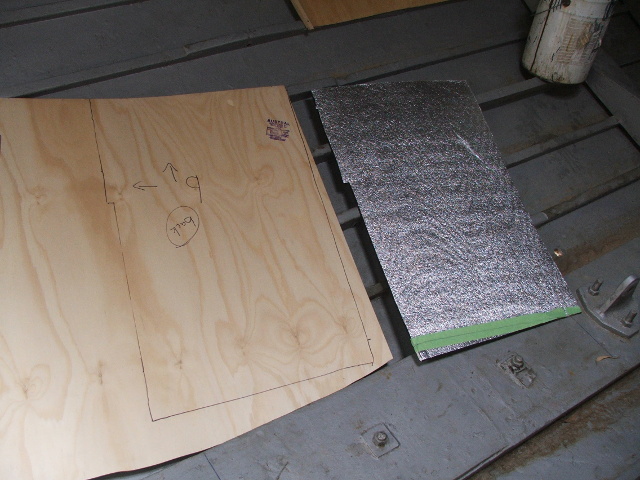

We are actually using the insulation to make act as a template to get the shape of the plywood panels. Its stiff enough to hold shape, yet flexible enough to jam into corners to mark out the required contours.

The process is fairly quick and accurate enough for the task at hand, but we do end up with a lot of little off cuts.