At last the aft cabin top is on. It took ages to get it done due to me having a lot of work commitments, and a long string of damp cold days that were not suitable for gluing.

Unfortunately, putting the top on showed up a mistake I made way back when setting up the jig.

The problem was that I did not support the jig strongly enough underneath so that when we bent the timber to make up the laminated beams, the jig deflected downwards in the center.

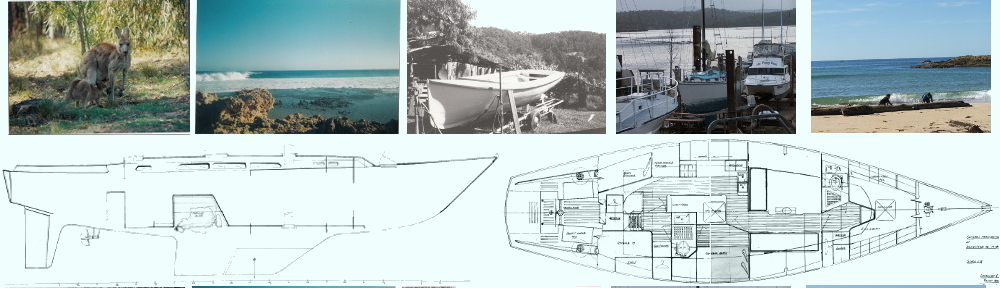

I noticed the deflection, but due to inexperience did not properly understand what it meant. The result is seen in the photos below.

Fortunately this is not a complete disaster. The access hatch for the aft cabin will be cut into where the deflection is worst so we will cut out the worst affected areas. Around the edges we will pack with plywood and fair up the cabin top to so it does follow a nice line.

Arrrhhh!! more work !! an untidy job !! very disappointing !!!

On a brighter note we also filled the hole where the original access hatch was, so now we only have the cockpit area to fill construct and the boat will be sealed up again.

A new rudder

A while ago I mentioned that the rudder stock was badly corroded. As it turned out there was nothing we could do to repair it. We decided to make a new one as an exact copy of the original but using stainless steel instead of plywood.

It was an expensive option, but the rudder is the single most important moving bit on the boat and well worth spending the money on to get it right.

A rudder mistake

In fitting up the new rudder we found and fixed another error, this time made by the original builders of the boat and potentially much more serious.

It seems a bit hard to believe, but when the rudder skeg was constructed it was not straight but bent slightly aft. This meant that the bottom of the skeg was about 20mm out of line from the top.

This was not in itself a problem, but the holes for the rudder stock were bored through the hull as if the skeg was straight.

The result of this was that when the rudder was fitted the stock was going through the bearings at a slight angle instead of being straight. Of course this meant the rudder did not turn properly in the bearings, and it explains why the bottom bearing was seized onto the rudder stock.

Well we fixed the problem by shaving the skeg to bring it into line with the holes. Now finally we should be able to have a rudder that turns easily as it should.

Its sort of interesting to realise that even professional boat builders make mistakes. It does not make me feel any better about the ones I make, just that I’m not alone in making them.

I think like a lot of things, the art of boat building is making your stuff-ups look like you meant them in the first place